The future belongs to robots. Or rather, cobots. This peculiar species of robots that bring out the best of themselves in cooperation with people will represent 8.5% of all industrial robots by 2022, according to data from Statista. But this is nothing: in 2027, cobots will account for 30% of the robotics global market, according to Interact Analysis forecasts. They also point out that China, North America, APAC and Eastern Europe will be the territories that will lead the adoption of collaborative robots in the industry of the next five years.What are cobots?

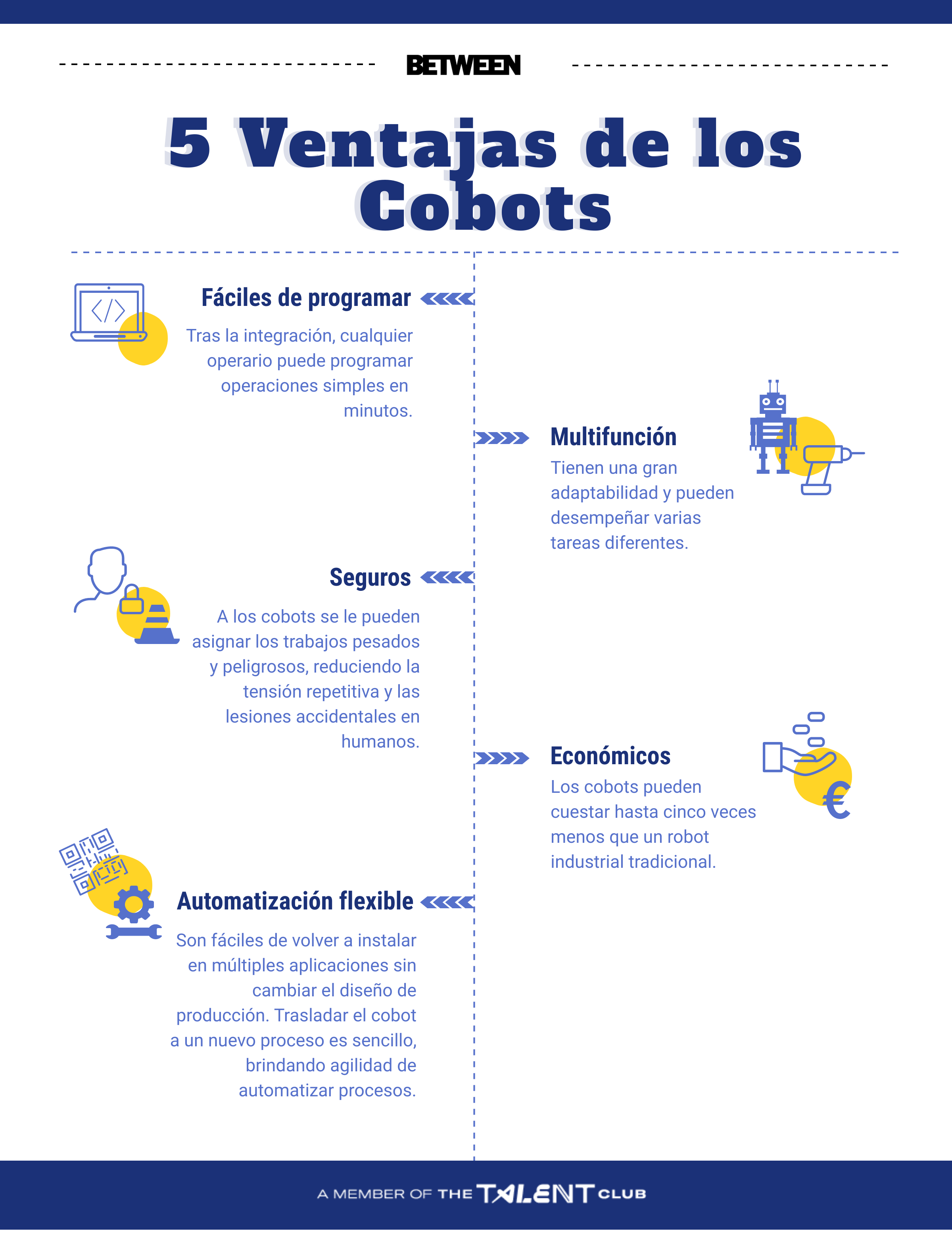

Cobots or collaborative robots are programmable machines that automate repetitive or heavy tasks through teamwork with humans. They stand out for their flexibility and their ability to adapt to changing situations, if production demands vary, it is possible to train them to meet the new requirements.

Cobots help strike the right balance between mechanization and manual intervention in manufacturing processes required by Industry 4.0.

How is a collaborative robot different from other robots?

Cobots differ from other robots in that:

- They do not replace the human factor in the performance of tasks, but rather multiply the capacities of people to carry them out more efficiently and quickly, and with fewer errors.

- They can (and should) operate in open spaces shared with flesh and blood workers, without fear that their presence will cause any accident.

- Its programming process is very simple, within the reach of operators with basic knowledge. Normally, it is enough to carry out the movements step by step with the cobot that we want it to execute by itself. Afterwards, the collaborative robot will repeat and refine them until it guarantees the achievement of the desired result in the optimal way.

- They are usually relatively light (less than nine kilos) and, therefore, easy to move wherever they are needed within the factory.

Cobots examples

The handling of goods, the assembly of products and the picking have been, until now, the main uses of cobots within the manufacturing industry, the automotive industry and the warehouses. However, in the coming years it will not be rare to find them in areas such as logistics, the health sector or services. Some of the most prominent examples of cobots are those used in:

- The assembly lines. With collaborative robots, manual intervention in the tasks of placing and fixing the parts decreases. The specialists focus on carrying out the necessary tests and quality controls before marketing.

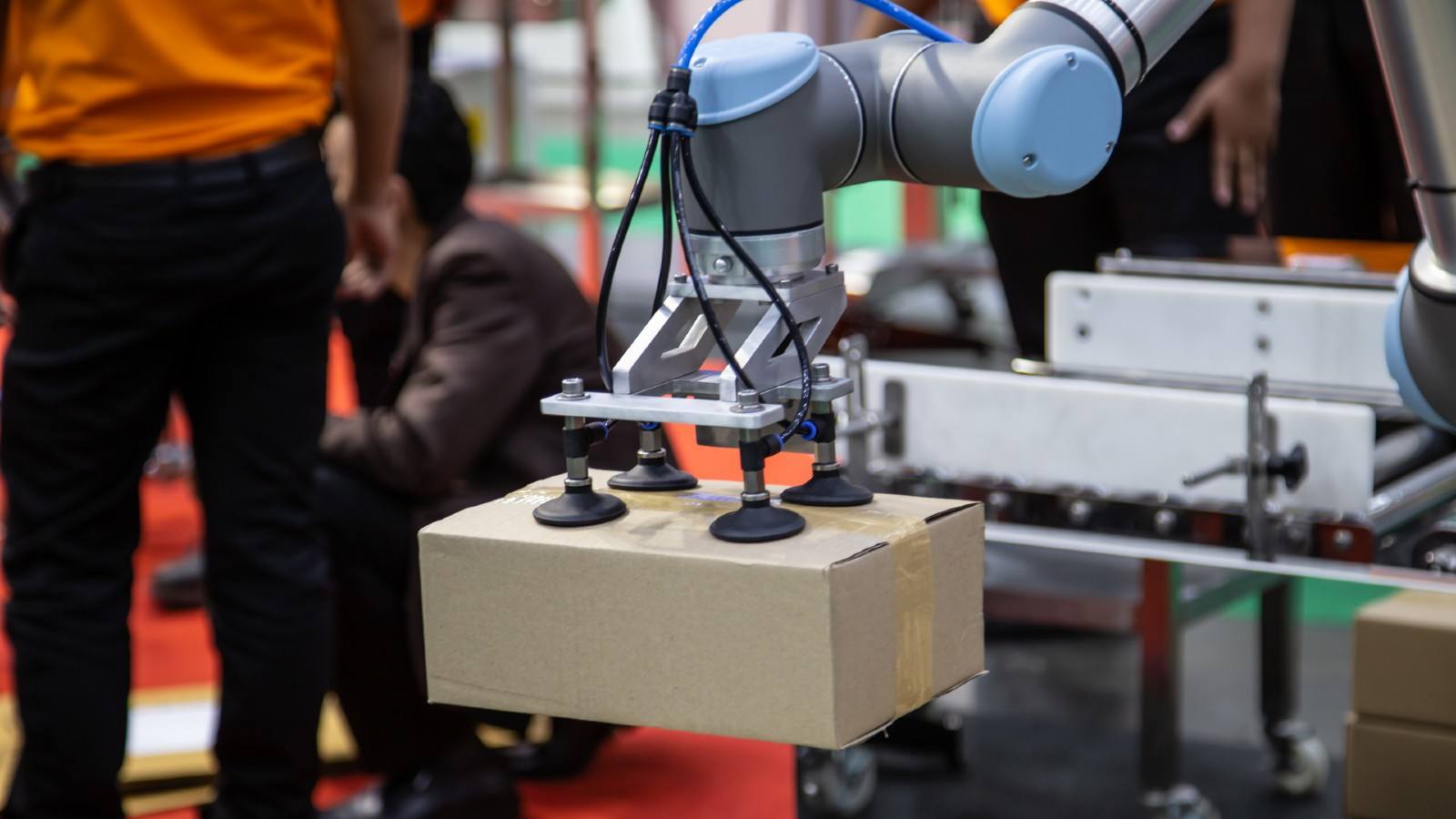

- The movement of bulky or heavy items. Cobots relieve operators in the loading of large and / or heavy objects. They are the ideal solution to maintain performance levels in companies where the average age of the workforce is on the rise.

- The development of repetitive actions. Carrying out the same movements over and over can cause injury and premature physical deterioration. Cobots increase the welfare of the workers, replacing them in the most painful activities.

- The preparation of orders in the warehouse. Cobots can take care of collecting the requested goods, planning the fastest route within the warehouse; and deposit them in the packaging area.

The cobots role in the 4.0 industry

We have insisted on flexibility and security as the undisputed strengths of cobots. But these modern assistants have other virtues that make them indispensable within Industry 4.0

- They are part of the Internet of Things (IoT). The implementation of 5G will facilitate the instant intercommunication of devices and, of course, that of cobots with each other and with other hardware, such as industrial 3D printers.

- They contribute to decentralizing decision-making. The interoperability of collaborative robots makes it easier to coordinate production resumes and interruptions, as well as the introduction of modifications during the process.

The integration of cobots in the automation environment typical of Industry 4.0 reduces costs and increases productivity, in addition to homogenizing and improving the quality of production.